Related Products

Performance overview

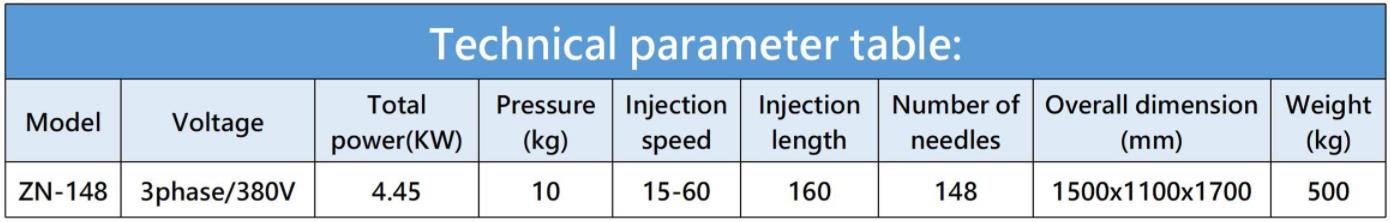

◆ This machine adopts microcomputer control, chain plate feeding, accurate step distance, and the injection needle is controlled by pneumatic spring, which can really achieve bone injection. The injection pressure, injection rate, step distance and speed can be accurately adjusted according to the size of the injected material and the organizational structure of the injected material, which can achieve the ideal injection effect. In addition, the machine adopts two-stage filtration to prevent needle blockage, and is equipped with a wind needle passing device, which is simple to operate and convenient to maintain. It is an ideal equipment for meat processing.

◆ This machine adopts servo drag chain conveying system on the basis of ordinary brine machine, which makes it more accurate and convenient to adjust the conveying step.

◆ Controlled by touch screen, the parameters of the injection machine can be stored according to different formulas. (parameters can be stored, and there is no need to adjust after the first debugging)

◆ The new injection speed is stable and controllable, and layered injection can meet the one-time injection completion of high injection rate.

◆ The reasonable configuration of needles + optimized layout of needles + precise numerical control can be achieved at one time under any injection rate. (multiple injections are not required)

◆ The brine pump adopts quantitative high-pressure pump, which has strong corrosion resistance, high pressure and uniformity. It is a necessary condition to realize foggy injection,high viscosity materials can be injected.